Description

Non-contact moisture analyzer Online NIR Moisture Sensor for the Food Products Industry Near Infrared Measurement

Produce More & Waste Less Improve Food Manufacturing Production with Moisture Control

PRODUCT INFORMATION

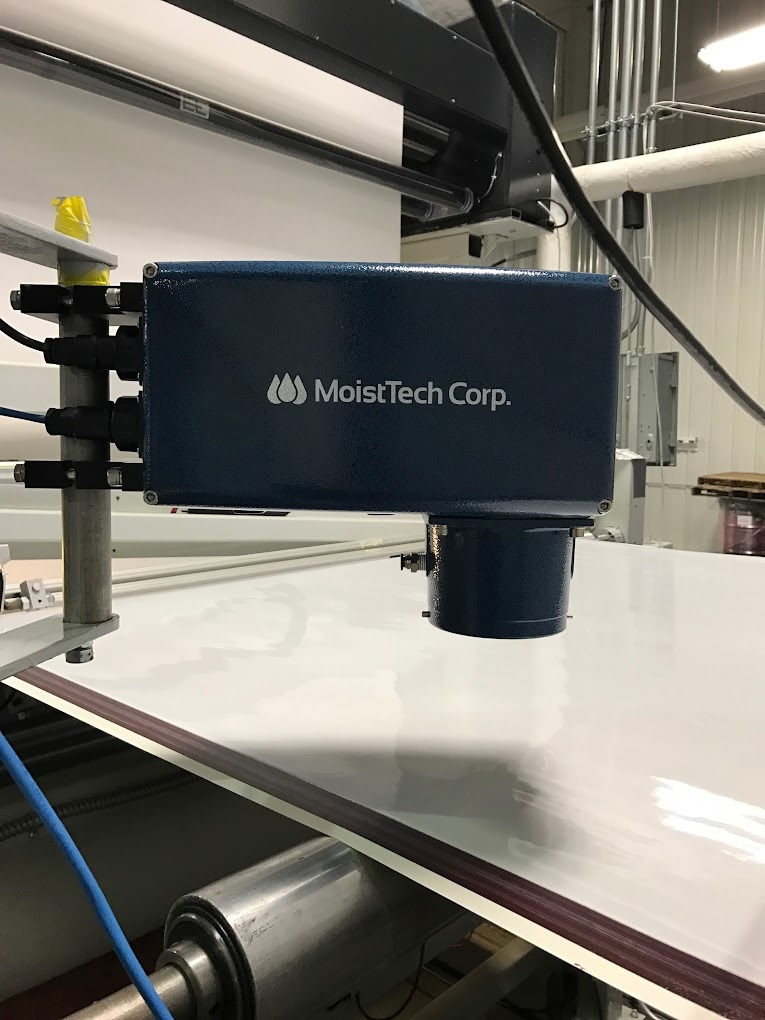

MoistTech developed the 3000-IP67 online NIR sensor to withstand

wash-downs, dusty / dirty environments, and to protect it against

the effects of immersion. Its rugged stainless steel enclosure

makes it ideal for the harshest environments, aggressive process

applications and the industry’s extreme temperatures. IP67

include an integrated air vortex or liquid cooling system that is

rated from 0°C to 93°C (200°F); additionally, insulation wraps are

available.

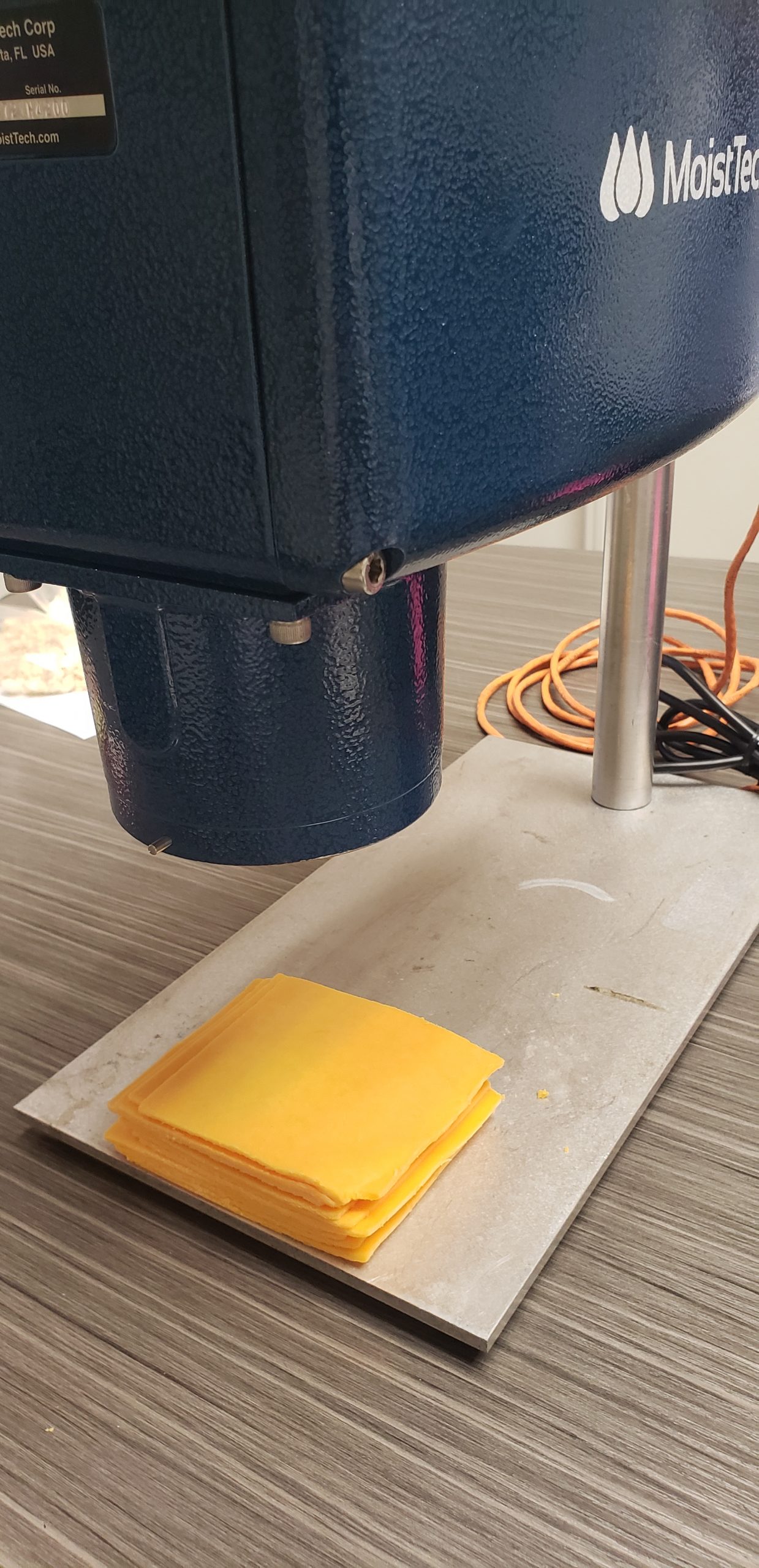

Insensitive to material variations such as particle size, material

height and color, the IR-3000 provides continuous, reliable readings.

It’s one-time calibration, maintenance free, drift free optical design

allows operating personnel to confidently make immediate process

adjustments based on real-time measurements.

Production efficiency improvements due to accurate real-time

measurements provide both energy savings and potential

increased productivity with lower material losses.

The IR-3000 uses state-of-the-art components allowing

installation in the most extreme locations. As result of MoistTech’s

advanced digital processing, only the IR-3000 provides true data

regardless of gaps and interruptions of product flow on the belt or screw conveyors.

KEY BENEFITS

• Insensitive to Material Variations – particle size, material height

and color do not affect the sensor

• One-time Calibration & Zero Drift Over Time

• Maintenance Free

• Product Quality Monitoring – allows immediate production line

adjustments to improve product quality and consistency

• Process Optimization – allows 100% monitoring of your

production process to reduce product that is “out of specification”

• Fuel Consumption Savings – reduce your energy usage as

the drying/cooking process can be controlled resulting in a

reduction in energy consumption

• Water Savings – reduce your water usage by continuously

monitoring moisture content

• Dust Prevention – help reduce the risk of explosion due to dust

INSTALLATION LOCATIONS

The sensors can be installed using the bracket on the back

of the sensor 4”-16” (inches) from the product. The MoistTech

sensor has many options for installation including:

• Belt, Screw, Drag & Enclosed Conveyors

• Chutes, Cyclones & Bins

• Dryer In/Out

• Webs

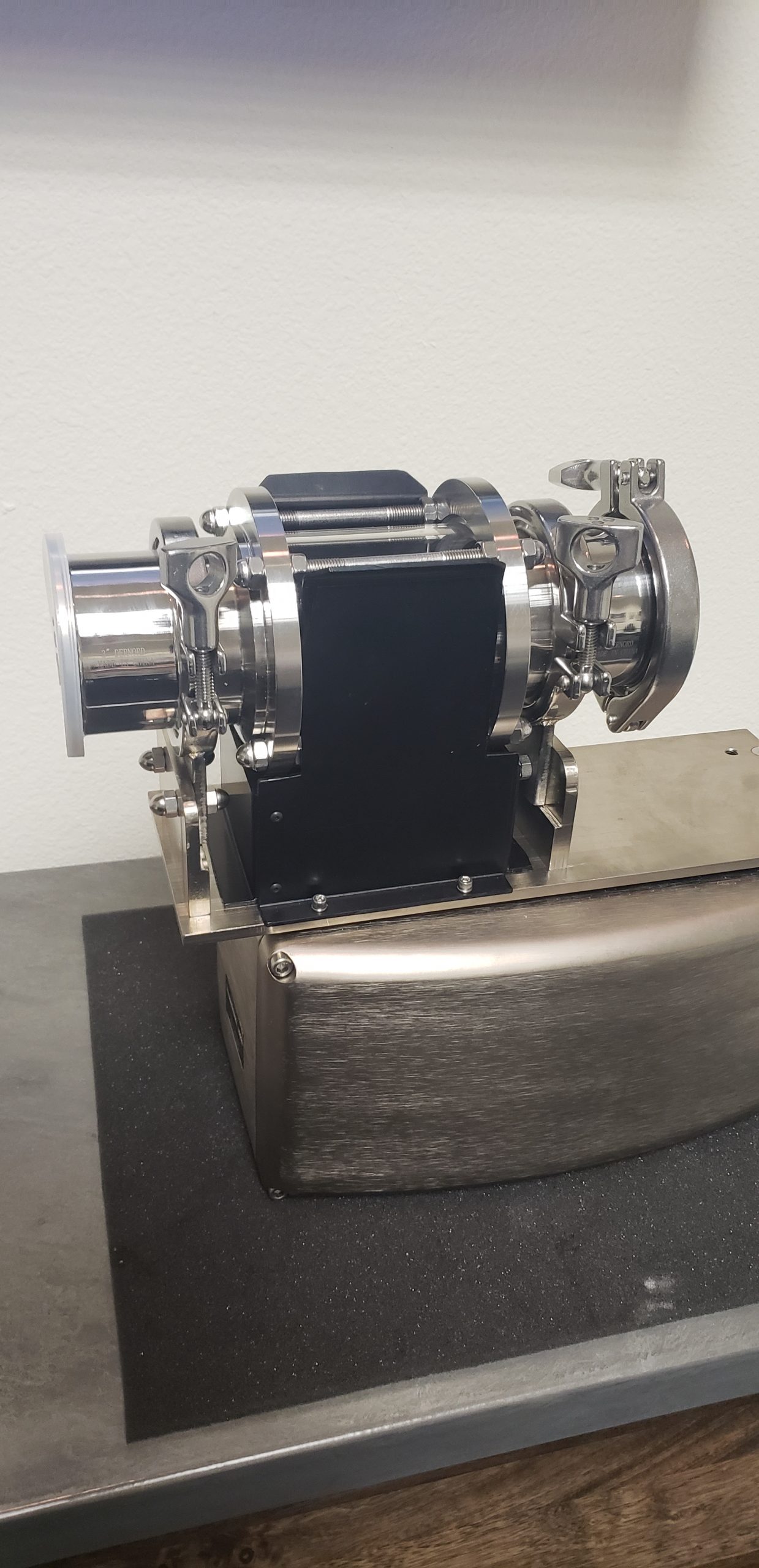

• Pipeline or Pneumatic Conveying using our Flange

window or Sampler options.

NEAR INFRARED (NIR) TECHNOLOGY

All molecular bonds absorb specific wavelengths

of light. Hydrogen bonds including O-H (water);

C-H (hydrocarbon) and N-H (ammonia) all absorb

strongly in the NIR spectral region. The amount of NIR

energy reflected at a given wavelength is inversely

proportional to the quantity of absorbing molecules in a product.

The NIR technique is a non-destructive, noncontacting measurement. MoistTech’s sensor utilizes multiple wavelengths of NIR light, projected onto the product at a very high repetition rate. The reflected light is then measured using a digitally enhanced

detection system and thousands of data points are sampled every second.